Cantilever Racking

OUR TOP SELLING PRODUCTS

Click a product to learn more

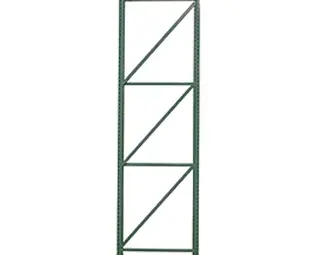

Utilizing cantilever racking can help make accessing products more accessible and provide better flexibility when operating inside a warehouse, manufacturing office, or industrial facility. Cantilever racking is designed to hold different inventory of varying lengths. These racks are able to store any length of material or product, which can help in a variety of industries that struggle to find storage for awkward lengths or heavy products.

BL Pallet Racking offers cantilever racking that can be customized to your unique needs and products. Cantilever racking can be single-sided or double-sided to change the layout of your warehouse for better efficiency. We also offer new racking and used options to fit any budget and improve business operations without financial ruin. Learn more about how cantilever racking can improve your business operations, warehouse safety, and storage below.

Storage For Lumber, Pipes, Furniture, And More

These sturdy racking systems are fully adjustable to your exact dimensions and can hold a variety of materials, including carpet rolls, pipes, lumber, furniture and furniture parts, sheet metal, and other bulky items. Awkward-shaped materials are often difficult to store properly, so cantilever racking can help you have a more organized space with easy access to what you need. Because they don’t have front columns to obstruct a load, they are ideal for all types of industries.

Different Cantilever Offerings

Depending on your business needs, there are a few different options to help maximize the space you have to work with. Below, we will discuss the different offerings that come with cantilever racks.

- Structural Cantilever: Ideal for automated retrieval systems and is taller than roll-formed racking. It can support more weight and is extra durable.

- Roll-Formed Cantilever: These are less expensive than structural racking and can be used in just as many capacities. It holds less weight but is able to work for most warehouse operations.

- Double-Roll Out: This option acts like a type of drawer to help you store long items without reaching. The roll-out rack allows full access to materials while limiting accidents. This has more storage capacity than a single-roll out.

- Single-Roll Out: These racks are only accessible from one side but help to keep items off the floor. Can be accessorized with dividers and adjustable pins to take better control of inventory.

Racking Vs. Shelving

While both of these storage options can be helpful in business efficiency, some industries may benefit from racking over shelving. Racking is primarily used for bulk storage and awkward-length items. Shelving is for pallet storage and keeping inventory in check. Shelving is typically made of metal or wood, and cantilever racking is made of heavy-duty metal or steel.

More About Cantilever Racking

Still curious about our racking options and how they can serve you? BL Pallet Racking knows that pallet racking and cantilever racking can help the overall look, feel, and function of your business. Learn more from the FAQs below.

need to speak to someone today?

Call Today and Speak with One of Our Specialists.

SEE WHAT OUR CLIENTS ARE SAYING

FREQUENTLY ASKED QUESTIONS

Make an informed decision about business storage

-

What Are The Risks Of Overloading A Racking System?

While cantilever racking is durable and capable of handling heavy items, there is a limit. Overloading a rack could result in the total system collapse, which could trigger a domino effect in other nearby racks or cause injury to those working in a warehouse. Overloaded racks are unstable and dangerous, even if they don’t immediately topple over. The products on the racking system could also come loose and fall, hurting the floor or employees.

-

How Does A Cantilever Rack Stay Up?

Through the quality construction of a rack, a solid base, and stabilizing braces, the cantilever racking will remain upright. Vertical columns are made of heavy-duty steel and are anchored to the base to make up the main part of the rack. Load arms are also part of what helps keep the rack upright when holding heavy items. These arms extend from the vertical columns to distribute the weight of the inventory. X braces are used between the columns to provide stability as well as bolting the system together and to the floor.

-

Can I Alter Cantilever Racking After It Has Been Installed?

Yes, racking can be altered after installation to help keep your business flexible and adaptable. Modifications can impact the load capacity of a racking system, so make sure to keep that in mind when adding anything to your unit. Most racking systems can change in arm length, number of levels, and width without the need to purchase new products or an entirely new system.

Have More Questions? Send Us a Message